PRIMARY STRUCTURE

Our pre-engineered buildings are custom-designed to meet your exact requirements. The most common Primary Framing systems are shown below.

Practically any frame geometry is possible. Consult a KK PREFAB representative for your specific requirements.

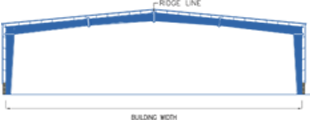

RIGID FRAME CLEAR SPAN (RFCS)

- Recommended Span 20-40M

- Suitable for ware houses, godowns, workshops, Industrial buildings having clear span requirement.

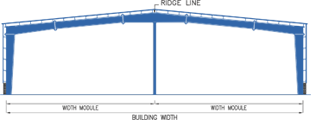

RIGID FRAME MULTI SPAN 1 (RFMS-1)

- Recommended Span 30-50M

- Suitable for large span buildings without a valley gutter.

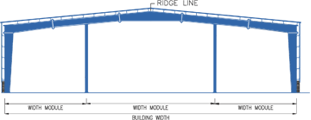

RIGID FRAME MULTI SPAN 2 (RFMS-2)

- Recommended Span 40-60M

- For span greater than 48m, it is economical to go for RFMS-2 frame than RFMS-1

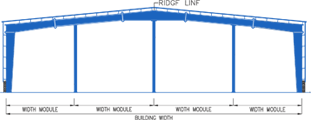

RIGID FRAME MULTI SPAN 3 (RFMS-3)

- Recommended Span 50-75M

- They are economical than RFMS-2 for spans greater than 72m

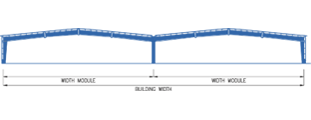

RIGID FRAME MULTI GABLE 1 (RFMG-1)

- Recommended Span 50-100M

- Economical than RFMS-1 but with valley gutter.

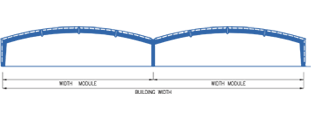

RIGID FRAME MULTI GABLE 2 (RFMG-2)

- Recommended Span 50-100M

- Economical than RFMS-1 but with valley gutter.

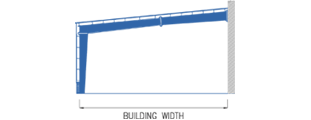

RIGID FRAME SINGLE SLOPE

CLEAR SPAN 1 (RFSS-1)

CLEAR SPAN 1 (RFSS-1)

- Recommended Span 6-18M

- Suitable for extension of execting building

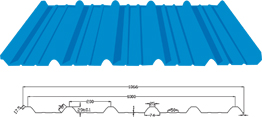

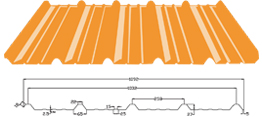

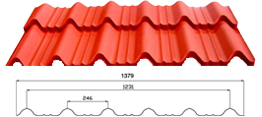

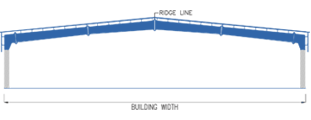

ROOF SYSTEM

(RCC COLUMN NOT IN OUR SCOPE)

(RCC COLUMN NOT IN OUR SCOPE)

- Recommended Span 40-60M

- For span greater than 48m, it is economical to go for RFMS-2 frame than RFMS-1

RIGID FRAME LEAN TO (RFLT-1)

- Recommended Span 6-20M

- Suitable for extension of execting building